Feeding the Material

![]()

THIS PAGE IS UNDER CONSTRUCTION!

PLEASE CHECK BACK SOON!

Feeding the Material

There are a wide variety of sewing machine feeding mechanisms designed to handle the broad range of materials used in the industry. The following are brief descriptions of the most common feed mechanisms. One of the most common parts you will read about on this page is the "feed dog", displayed below in case the term is not familiar.

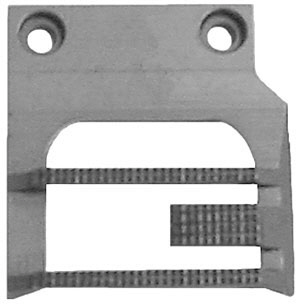

Feed Dog:

(viewed from the top)

The feed dog is located underneath the "needle plate" or "throat plate" (see below). Feed dogs usually have thin rows of metal with small "teeth" which fit into the open slots in the needle plate and grab the material from the bottom.

Drop Feed: A type of feed which alternately engages and disengages the feed dog from the underside of the material.

Differential Feed: A type of drop feed with two feed dogs arranged in tandem which move differentially. Machines with differential feed typically can be adjusted for gathering, stretching, or conventional drop feed sewing.

Needle Feed: A type of feed which has a "vibrating" or swinging needle bar that allows the needle to move the material ahead one stitch length. The needle enters an elongated hole in the needle plate after passing through the material.

Alternating Pressers or "Walking Foot": A type of feed consisting of two presser feet, a feeding or "vibrating" presser (inside) and a lifting presser (outside). The presser feet work in combination and are arranged so that they press down alternately on the material. This makes the alternating pressers appear to "walk" over the fabric, and facilitates handling of materials with uneven thickness.

Compound Needle Feed: A type of feed with a vibrating (swinging) needle bar synchronized with a drop feed motion. In most cases, the needle hole is in the feed dog.

Unison Feed: A type of feed consisting of a vibrating needle bar, alternating presser feet, and a bi-directional feed dog which comes flush to the surface of the needle plate. These three feed elements combine to provide optimal feeding of difficult materials.

Puller Feed: A type of feed consisting of an independent mechanism with one or more rollers, which help feed the material from the machine. At least one of the rollers are driven continuously or intermittently.

Reversible Feed: A type of feed where the direction of the drop feed can be reversed so the the material feeds towards the operator instead of away.

Upper Feed: A type of feed where a positively driven feeding foot alternately engages and disengages the upper side of the material.

Universal Upper Feed: A type of feed like Upper Feed above, except that the direction of the feeding foot can be altered, so that directional feeding of the material is possible.

Upper and Under Feed: A type of feed consisting of alternating presser feet operating in unison with a drop feed.

Independent Upper and Under Feed: A type of feed which consists of a feeding foot operating in conjunction with a drop feed. The lengths of stroke are independently adjustable so that the upper or under side of the material may feed faster, slower or at the same time (synchronized).

Under Wheel Feed: A type of feed where a wheel is constantly engaged with the underside of the material. The feed can be continuous or intermittent, and continuous wheel feed machines use needle feed as well.

Upper Wheel Feed: A type of feed where a wheel is constantly engaged with the upper side of the material.

Upper and Under Wheel Feed: A type of feed where two wheels are constantly engaged with both the under and upper sides of the material. The rate of rotation of the wheels may be synchronized or independently adjustable according to need.

Cup Feed: A type of feed used on machines where the needle operates in the horizontal direction. Feeding is accomplished either by passing the material between the edges of two rotating discs (sometimes cup shaped) or by passing the material between one disc and a presser surface.